Schmierölkreislauf

+5

schorsche ϯ 14.06.2023

Brummbaehr

Kallebadscher

güllmek

Waterbrunn

9 verfasser

CX GL500-650 Forum :: Technisches :: Technikecke :: Motor

Seite 3 von 4

Seite 3 von 4 •  1, 2, 3, 4

1, 2, 3, 4

Re: Schmierölkreislauf

Re: Schmierölkreislauf

Wie ist denn eigentlich der Verschleiß an den Kiphebelwellen bei den 650er Motoren?

_________________

Ist Spannungsabfall eigentlich Sondermüll?

Digitale CDI-Zündung

Arduino-CDI --> Anschlussplan --> Erprobung/Test

Stammtisch WilderWesten

Re: Schmierölkreislauf

Re: Schmierölkreislauf

wird wahrscheinlich gleich sein, wie bei der 500er? (also E/GL)

die Beanspruchung ist ja auch höher, da macht es die Vorteile der höheren Förderleistung wieder zu Nichte.

(nur meine Meinung )

)

die Beanspruchung ist ja auch höher, da macht es die Vorteile der höheren Förderleistung wieder zu Nichte.

(nur meine Meinung

zockerlein- Anzahl der Beiträge : 1342

Anmeldedatum : 07.07.14

Alter : 27

Ort : Nürnberg

Re: Schmierölkreislauf

Re: Schmierölkreislauf

Ich muss mal nachschauen wie der Verschleiß bei den 650er Motoren ist bezüglich den Kipphebelwellen. Das wird aber was dauern, da ich zu Zeit ein wenig Überfordert bin mit dem was ich hier an 650er Ersatzteilen hab.

Ob der Verschleiß gleich ist

Die Belastung der Kipphebel/ Nockenwelle ist eigentlich gleichzusetzen wie bei den 500er Motoren. Die Kurbelwelle, Pleuel, Getriebe, Kupplung und Endantrieb vom 650er Motor, unterliegen nach meiner Einschätzung einer höheren Belastung aus.

Ich habe schon zahlreiche 500er Motore gehört, die von den Köpfen her am klackern waren obwohl das Ventilspiel richtig eingestellt war. Bei den 650er Motoren ist dies mir noch nicht so aufgefallen. Es kann aber auch sein, dass es daran liegt, dass es viel mehr 500er gibt als 650er.

Ob der Verschleiß gleich ist

Die Belastung der Kipphebel/ Nockenwelle ist eigentlich gleichzusetzen wie bei den 500er Motoren. Die Kurbelwelle, Pleuel, Getriebe, Kupplung und Endantrieb vom 650er Motor, unterliegen nach meiner Einschätzung einer höheren Belastung aus.

Ich habe schon zahlreiche 500er Motore gehört, die von den Köpfen her am klackern waren obwohl das Ventilspiel richtig eingestellt war. Bei den 650er Motoren ist dies mir noch nicht so aufgefallen. Es kann aber auch sein, dass es daran liegt, dass es viel mehr 500er gibt als 650er.

Polierteufel ϯ 24.05.2021- verstorben

- Anzahl der Beiträge : 570

Anmeldedatum : 02.03.15

Re: Schmierölkreislauf

Re: Schmierölkreislauf

Brummbaehr schrieb:Wie ist denn eigentlich der Verschleiß an den Kiphebelwellen bei den 650er Motoren?

Soweit ich es gesehen habe, war er schon etwas geringer. Vor allem aber gleichmäßiger, weil sich das Muster der Schmiernut nicht einarbeitet.

Ich habe gestern auch gesehen, dass es die verbesserten Lagerbuchsen, dann allerdings in Kombination mit den einfachen Wellen, auch bei CX 500-Kipphebelböcken gegeben hat.

Die Wellen mit den Nuten und den beiden Bohrungen scheinen auch erst bei späteren 650ern zum Einsatz gekommen zu sein. Der erste 650er Motor, den ich zerlegt habe, hatte sie noch nicht.

f104wart- Anzahl der Beiträge : 11446

Anmeldedatum : 24.02.13

Alter : 67

Ort : 35315 Homberg Ohm

Re: Schmierölkreislauf

Re: Schmierölkreislauf

As for the hardness of the rocker shafts.... because I have seen you are talking about it, so to make things clear.

The testing was done by the company that produced the shafts for me (they are true professionals, they are in the business of shafts and piston pins for like 30 years now), and the result of their testing is quite unquestionable.. so if they say it is 15hrc..., (no matter how ridiculous it might sound), then it is. Try to file them and you will see how soft they are. (The camshafts are also very soft... I have read on the forum your tinkering about why they pit, about the symetry of lower rocker arms and other stuff - too much thinking I suppose - the main problem is... the camshafts are too soft -and this is where the thinking ends)

The rockwell scale, however, is not accurate under 20hrc.... so... the shafts may be even 20hrc (or even lower than 15hrc), but not above.

These numbers are also confimed at the USA CX500 forum, somebody measured them at 11hrc ...

...

source: http://cx500forum.com/forum/general-discussion/2805-rocker-shafts-upper-rockers-2.html

So now we have two separate tests saying below 20hrc and I will repeat, below 20hrc the rockwell scale may show even 8hrc for 15hrc hardness, let them be whatever, they are too soft anyway.. you won't repair it with the better oil flow, you will only make them last a bit longer... I know it is hard to believe that honda used so weak material there but they did..

The measurement on mine was done on a healthy place of the shaft - not where it was damaged.

___________________

The oil pumps.. It is a very good idea to adapt the 650 one, the pressure will not grow but the flow will.... I was thinking even of buying one but I was offered a very good 500 here on the forum, so if your cx500 pump is as good as new you cannot be wrong with it...

Why then is the 650 pump 30% more efficient than the 500 one.... perhaps because of the different rocker shaft oiling design. You do realise that each hole/place in the engine from which oil gets out will reduce the pressure/flow to the parts that lie farher from the pump and also overally (make an experiment at your house, open each water tap and you see the flow will start to drop , if the engine is worn, the oil flow behaves in the same way).

, if the engine is worn, the oil flow behaves in the same way).

So, if honda decided to drill a hole in the rocker shafts to oil the valve tappets (because I believe the hole in the rocker shaft is to improve the tappet oiling), then by opening the oil passage at the top of the engine, they must have comprised the loss of the oil pressure by making a bigger pump so the crankshaft will be well oiled. I know you are going to remind me that there is an oil jet before oil enters the cylinder head - but still, the pressure may drop. By the way, has anyone looked at the sizes of the cylinder oil jets that are on the 650, perhaps they are a bit bigger??

So that's why I believe, an "open style design" of oiling of the shafts used in the 650, is not that great for the 500 (especially when you have a bit worn oil pump and a bit worn engine).... this is also the reason why I decided to keep the 500 solution on the shafts... because it keeps oil in the shafts and keeps pressure before the cylinder head, and then it will only flow out of the rocker shafts when the pressure pushes it to the outside - perhaps not that effective when the bike is idling or starting. I opened the covers on the working engine. I spent so much money that I have become oversensitive, the shafts were wet at each end, assuming the hardness of the new material it should work (but who knows... mechanics can be a bitch sometimes )

)

I will be reading about your observations... I am using a translator it is a bit difficult to follow but I will try to share my knowledge if I can...

The testing was done by the company that produced the shafts for me (they are true professionals, they are in the business of shafts and piston pins for like 30 years now), and the result of their testing is quite unquestionable.. so if they say it is 15hrc..., (no matter how ridiculous it might sound), then it is. Try to file them and you will see how soft they are. (The camshafts are also very soft... I have read on the forum your tinkering about why they pit, about the symetry of lower rocker arms and other stuff - too much thinking I suppose - the main problem is... the camshafts are too soft -and this is where the thinking ends)

The rockwell scale, however, is not accurate under 20hrc.... so... the shafts may be even 20hrc (or even lower than 15hrc), but not above.

These numbers are also confimed at the USA CX500 forum, somebody measured them at 11hrc

...

...u are probably correct on the nitriding not being neccessary. While I can't remember the actual figures {I am certainly not a metallurgist} I think the original shaft from Honda only came to around 11 rockwell when tested. I questioned in light of this with the machine shop if nitriding was in fact neccessary as it struck me as overkill but basically he insisted on it as if the new shafts did wear it would be an issue with the parts he had made.

source: http://cx500forum.com/forum/general-discussion/2805-rocker-shafts-upper-rockers-2.html

So now we have two separate tests saying below 20hrc and I will repeat, below 20hrc the rockwell scale may show even 8hrc for 15hrc hardness, let them be whatever, they are too soft anyway.. you won't repair it with the better oil flow, you will only make them last a bit longer... I know it is hard to believe that honda used so weak material there but they did..

The measurement on mine was done on a healthy place of the shaft - not where it was damaged.

___________________

The oil pumps.. It is a very good idea to adapt the 650 one, the pressure will not grow but the flow will.... I was thinking even of buying one but I was offered a very good 500 here on the forum, so if your cx500 pump is as good as new you cannot be wrong with it...

Why then is the 650 pump 30% more efficient than the 500 one.... perhaps because of the different rocker shaft oiling design. You do realise that each hole/place in the engine from which oil gets out will reduce the pressure/flow to the parts that lie farher from the pump and also overally (make an experiment at your house, open each water tap and you see the flow will start to drop

So, if honda decided to drill a hole in the rocker shafts to oil the valve tappets (because I believe the hole in the rocker shaft is to improve the tappet oiling), then by opening the oil passage at the top of the engine, they must have comprised the loss of the oil pressure by making a bigger pump so the crankshaft will be well oiled. I know you are going to remind me that there is an oil jet before oil enters the cylinder head - but still, the pressure may drop. By the way, has anyone looked at the sizes of the cylinder oil jets that are on the 650, perhaps they are a bit bigger??

So that's why I believe, an "open style design" of oiling of the shafts used in the 650, is not that great for the 500 (especially when you have a bit worn oil pump and a bit worn engine).... this is also the reason why I decided to keep the 500 solution on the shafts... because it keeps oil in the shafts and keeps pressure before the cylinder head, and then it will only flow out of the rocker shafts when the pressure pushes it to the outside - perhaps not that effective when the bike is idling or starting. I opened the covers on the working engine. I spent so much money that I have become oversensitive, the shafts were wet at each end, assuming the hardness of the new material it should work (but who knows... mechanics can be a bitch sometimes

I will be reading about your observations... I am using a translator it is a bit difficult to follow but I will try to share my knowledge if I can...

Re: Schmierölkreislauf

Re: Schmierölkreislauf

bc30se schrieb: So now we have two separate tests saying below 20hrc and I will repeat, below 20hrc the rockwell scale may show even 8hrc for 15hrc hardness, let them be whatever, they are too soft anyway.. you won't repair it with the better oil flow, you will only make them last a bit longer... I know it is hard to believe that honda used so weak material there but they did..

The measurement on mine was done on a healthy place of the shaft - not where it was damaged.

Paul, I aggree with you about the hardness, but I´m not sure about the oilflow of 500 solution.

The problem is, that the oil is pumped into the inner of rocker arms and from there it must flow into the bearings. The oil is taking the easiest way. That means, it will only reach these parts of the bearings and rocker shafts, which are not loaded and where the have the most bearing-clearance.

Due to we don´t have a rotation, but only an oszilating movement, the lubrication just there is not good.

...In my opinion the 650 solution is much better, because the oil comes out the wholes just inside the bearings and due to the radial groove it will reach all regions of the shafts inside the bearing.

They are the same. That means, that the different design of rocker schafts has no effect to the lubrication of the crankshaft bearings.bc30se schrieb:

By the way, has anyone looked at the sizes of the cylinder oil jets that are on the 650, perhaps they are a bit bigger??

I think, the "open Style of design" also is better the 500, even with the 500 pump. But - that´s true - of course it will be better with the 650 pump.

Another thing to optimize the oil flow is, to enlarge the wholes, where the oil is coming into the rocker shafts. These wholes are not drilled, they are generated only due to milling the cut-out for the cylinder head screws and drilling the wholes through the rocker shaft. They are very different and has a big burr.

f104wart- Anzahl der Beiträge : 11446

Anmeldedatum : 24.02.13

Alter : 67

Ort : 35315 Homberg Ohm

Re: Schmierölkreislauf

Re: Schmierölkreislauf

f104wart schrieb:

The oil is taking the easiest way. That means, it will only reach these parts of the bearings and rocker shafts, which are not loaded and where the have the most bearing-clearance.

Due to we don´t have a rotation, but only an oszilating movement, the lubrication just there is not good.

Hello

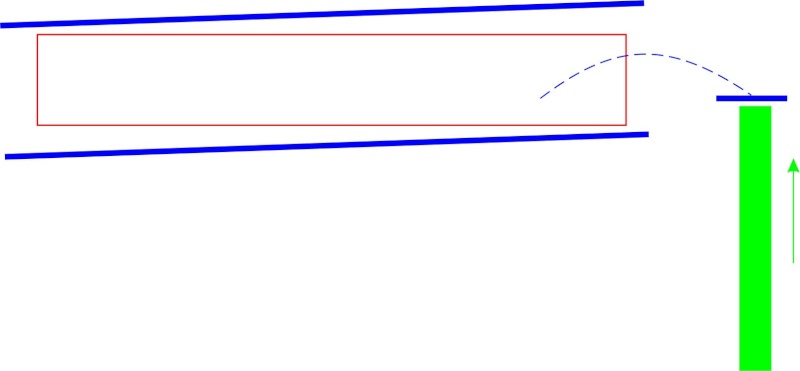

But there is still one more thing, you have this "oszilating" movement as you call it but.... because of the fact that the force comes from the arm that is pushed by the lifter.. in reality the whole arm has a tendency to bias:

Perhaps this is the reason why they fail - direct friction that you cannot eliminate... more oil may help, but again, it is about making them live a little bit longer.

So it is both, not enough oil is also true in the cx500 solution, but when I looked at mine working without the covers, the oil seems to flow out of the both sides of the shaft - perhaps because of the clearence that develops when the arm is pushed from under. That's why I even asked to have a little bit of more clearence made - like 0.03, so I still have more bias and that oil may flow even when the arm is pushed...

It seems that I do have some oiling and anyway it would be nice to see how long it is going to last with enforced elements there.

Re: Schmierölkreislauf

Re: Schmierölkreislauf

bc30se schrieb:... in reality the whole arm has a tendency to bias:

Yes, but not in the way as your drawing is shown.

...You don´t have one long bearing, you have two short ones. So the real situation is like this:

...There is no clearance for sufficient lubrication in yellow marked area, even if you make the clearance bigger.

Due to the oszillated action you will not have a hydrodynamic lubrication like you have in a slide bearing with rotation action.

...The yellow marked area ist the problem of the original 500 design. It will also be possible to design this side of shaft like at the 650 and the other side like at the 500.

But when you only optimize the hardness of the shaft, indeed you will not have the problem at the shaft in future, but you will get it at the bearing. It will get oval, if you want or not.

f104wart- Anzahl der Beiträge : 11446

Anmeldedatum : 24.02.13

Alter : 67

Ort : 35315 Homberg Ohm

Re: Schmierölkreislauf

Re: Schmierölkreislauf

I think you may not be right... the bushings are pressed into the rocker arms, if the rocker arm bends, the bushing don't stay straight.. they lean/work together with the direction of the arm, this is the shaft that stays in position, the bushings in the shaft take a different position. You must still remember that one time this is the tappet that pushes on the arm (from downside), and then when the valves depress, the shaft works in the opposite way being pushed by the valve springs, so the oil that was flowing in the upper part of the bushing is now squized, the pressure is created and it goes down.

This is not technically such a bad solution because conrod bearings work on the same principle... when the piston comes to the TDC, the oil pressure in the upper bearing shell in the conrod is at highest and it is pushed down... the only bad thing about the rocker shaft is that bias I have referred to... as you are saying, no paraller action there...

You see, the wear on the bushing is divided in half - the bushing is healthy inside, and worn outside.. it proves they don't align with the shafts in a straight manner:

At some partial area of the shaft - because they let's say 'half-rotate', there is going to be friction all the time because it is just such a design. Perhaps not poor design - materials are poor, but design is not and each design has some pluses and minuses.

You are right that with the harder shafts, the bushings will be shot first.. but.. when is it going to be? and even if they do fail, the they are cheap, you will just press the new ones, the shaft stays - much easier even every 30.000km.

This is not technically such a bad solution because conrod bearings work on the same principle... when the piston comes to the TDC, the oil pressure in the upper bearing shell in the conrod is at highest and it is pushed down... the only bad thing about the rocker shaft is that bias I have referred to... as you are saying, no paraller action there...

You see, the wear on the bushing is divided in half - the bushing is healthy inside, and worn outside.. it proves they don't align with the shafts in a straight manner:

At some partial area of the shaft - because they let's say 'half-rotate', there is going to be friction all the time because it is just such a design. Perhaps not poor design - materials are poor, but design is not and each design has some pluses and minuses.

You are right that with the harder shafts, the bushings will be shot first.. but.. when is it going to be? and even if they do fail, the they are cheap, you will just press the new ones, the shaft stays - much easier even every 30.000km.

Zuletzt von bc30se am So 6 März 2016 - 10:30 bearbeitet; insgesamt 1-mal bearbeitet

Re: Schmierölkreislauf

Re: Schmierölkreislauf

bc30se schrieb:I think you may not be right... the bushings are pressed into the rocker arms, if the rocker arm bends, the bushing don't stay straight.. they lean/work together with the direction of the arm,

Of course I know, but with Paint it was not possible to bring out it in a better way with the short lines. Your Photo is showing it better. But the problem in the yellow area still is the same.

f104wart- Anzahl der Beiträge : 11446

Anmeldedatum : 24.02.13

Alter : 67

Ort : 35315 Homberg Ohm

Re: Schmierölkreislauf

Re: Schmierölkreislauf

There is a set of 650 rocker arms that I can buy cheap now.. perhaps I will be tempted... you know.. in my case, I don't know if my engine will not blow tomorrow so perhaps any investments aren't that wise at the moment

ok... it was good to share arguments, I don't want to be impolite, I won't be disturbing you now, switch back to German;)

ok... it was good to share arguments, I don't want to be impolite, I won't be disturbing you now, switch back to German;)

Re: Schmierölkreislauf

Re: Schmierölkreislauf

The language is no problem for me. I like to change arguments and experiance with you very much.bc30se schrieb:ok... it was good to share arguments, I don't want to be impolite, I won't be disturbing you now, switch back to German;)

...The problem is, that the upper rocker-shafts are no more available and they are in bad condition in most of our engines.

The hardness is one thing, but if we want to start a reproduction, we should also think about the bushes and how to optimize the lubrication.

I would be very happy, if we find a solution and we can use your contacts to start a reproduction in Poland, because it would be much cheaper as in Germany. May be we can dio it together.

f104wart- Anzahl der Beiträge : 11446

Anmeldedatum : 24.02.13

Alter : 67

Ort : 35315 Homberg Ohm

Re: Schmierölkreislauf

Re: Schmierölkreislauf

I think bigger orders might be cheaper... Because of our new government with Mr Kaczynski, we have unstable currency now and the Euro went up, so.. better for you at the moment.

The 650 style shafts can be made... is there a reason to worry to improve the design so much? I don't know, after all you install new/better parts. If the old were made of worse materials and they were so durable, then the new ones should be much better.

I think whatever you do, it will be better than having old and used ones... and you know.. I am riding, and I will be riding her this season even more because I am going to restore the bike as a whole (still a lot of work), but I am waiting if the engine will not blow... because if it blows there will be no sense in doing anything.

The 650 style shafts can be made... is there a reason to worry to improve the design so much? I don't know, after all you install new/better parts. If the old were made of worse materials and they were so durable, then the new ones should be much better.

I think whatever you do, it will be better than having old and used ones... and you know.. I am riding, and I will be riding her this season even more because I am going to restore the bike as a whole (still a lot of work), but I am waiting if the engine will not blow... because if it blows there will be no sense in doing anything.

Re: Schmierölkreislauf

Re: Schmierölkreislauf

bc30se schrieb:The 650 style shafts can be made... is there a reason to worry to improve the design so much? I don't know, after all you install new/better parts.

Yes, I also thought so, but your objection was the bigger oil pump and I think, it´s legitimately to think about it.

May be it´s also good to design only the forced side like 650 and the other side like 500.

Bye the way: The old ones were good for a lot of years and a lot of kilometers. May be also the quality of the used oil is determinat for the lifespan.

My ideas went in the direction of 650 design, before (!) I saw the 650 rockers and I was happy to find it. So I´ve got a verification of my ideas, but your objection with the oil pump also is an important parameter.

To optimize as many 500drets as possible we must think with the 500 oil pump, but it must be sure, that the oil flow will be enough. I think it will, because the oil evenly and directely is coming inside the bushes and not has to find his way from the inside of rocker arm to the bushes at the ends of shafts, where it´s taking the way of least resistance at the biggest clearance of bearing bushes.

f104wart- Anzahl der Beiträge : 11446

Anmeldedatum : 24.02.13

Alter : 67

Ort : 35315 Homberg Ohm

Re: Schmierölkreislauf

Re: Schmierölkreislauf

I think a good 500 pump will be enough, unfortunately many of them are no good now... then even a little bit worn 650 will be better...

Re: Schmierölkreislauf

Re: Schmierölkreislauf

Going back to the subject, because I had been thinking still before and yesterday I read an interesting article which confirmed my thoughts... the article was about reducing the size of the oil grooves in modern production of plain bearings:

http://motofocus.pl/technika/8027/wplyw-rowkow-w-panewkach-glownych-na-osiagi

Do you realise that oil grooves in the bearings on the rocker shafts may actually make oiling much worse???

This is because normally when oil finds itself in between the bearing and the journal, it will be pressurised when it is under load. In our situation - the shaft is not rotating, it will be the left picture:

So once the rocker arms work, one part of the bearing is under load, it means oil is pressurised and it travels upwards to provide oiling on the top of the bearing.... when you make a groove, you will loose oil pressure...

...and what honda did with their grooves means that oil will return into the inside of the arm because the grooves are "closed" on the outer side and "open" on the inside.... it will make the oil flow out under load, it will reduce oiling on the top of the bearing, and also decrease the efficiency of oiling on the bottom...

http://motofocus.pl/technika/8027/wplyw-rowkow-w-panewkach-glownych-na-osiagi

Do you realise that oil grooves in the bearings on the rocker shafts may actually make oiling much worse???

This is because normally when oil finds itself in between the bearing and the journal, it will be pressurised when it is under load. In our situation - the shaft is not rotating, it will be the left picture:

So once the rocker arms work, one part of the bearing is under load, it means oil is pressurised and it travels upwards to provide oiling on the top of the bearing.... when you make a groove, you will loose oil pressure...

...and what honda did with their grooves means that oil will return into the inside of the arm because the grooves are "closed" on the outer side and "open" on the inside.... it will make the oil flow out under load, it will reduce oiling on the top of the bearing, and also decrease the efficiency of oiling on the bottom...

Re: Schmierölkreislauf

Re: Schmierölkreislauf

The article and the picture shows the hydrodynamic lubrication.

On the rocker arms there is a hydrostatic lubrication.

https://en.wikipedia.org/wiki/Fluid_bearing

On the rocker arms there is a hydrostatic lubrication.

https://en.wikipedia.org/wiki/Fluid_bearing

Gast- Gast

Re: Schmierölkreislauf

Re: Schmierölkreislauf

Guelli. There is no high pressure in the arms because pressure is held by the oil jet on the entry to the head... Do as you wish but from now on I will be reducing the size of oil grooves whenever I will be doing the bearings again...

PS. the article is not about the types of oiling, it is strictly about the influence of the size of oil grooves on the efficiency of oiling.. so logically - I assume, that if in the hydrostatic system, an oversized groove has an influence on the quality of lubrication, then in the hydrodynamic solution it will be even more substantial

no engineering on my part - only logics... I am not anyone above that...

edit:

and the manufacturers aint omniscient, it is not like in the 80s honda knew or gave as possibly the best solution they had, I don't know... if the CX hadn't been discountinued, perhaps they would have changed the design, because if you look at moto guzzi:

old type - CX directly copied the solution:

http://image.wikifoundry.com/image/1/KrkH7FKlhorVLBrMQKszXA39169/GW445H336

https://s-media-cache-ak0.pinimg.com/originals/8b/de/50/8bde506b9ddbfa2a2dc6dad58d222907.jpg

new type:

http://1.bp.blogspot.com/-txZNAe6foWw/VKXccxCgDtI/AAAAAAAAGzQ/ctJx22KREzE/s1600/MPC%2BBig%2BBore%2BRocker%2BArms.jpg

This is because motoguzzi V engines are the particular design they constantly develop, look at the roller tappets - so nice. Old moto guzzis must share the same problems that the CXes have...

PS. I like motoguzzi, but I don't have money for one...

PS. the article is not about the types of oiling, it is strictly about the influence of the size of oil grooves on the efficiency of oiling.. so logically - I assume, that if in the hydrostatic system, an oversized groove has an influence on the quality of lubrication, then in the hydrodynamic solution it will be even more substantial

no engineering on my part - only logics... I am not anyone above that...

edit:

and the manufacturers aint omniscient, it is not like in the 80s honda knew or gave as possibly the best solution they had, I don't know... if the CX hadn't been discountinued, perhaps they would have changed the design, because if you look at moto guzzi:

old type - CX directly copied the solution:

http://image.wikifoundry.com/image/1/KrkH7FKlhorVLBrMQKszXA39169/GW445H336

https://s-media-cache-ak0.pinimg.com/originals/8b/de/50/8bde506b9ddbfa2a2dc6dad58d222907.jpg

new type:

http://1.bp.blogspot.com/-txZNAe6foWw/VKXccxCgDtI/AAAAAAAAGzQ/ctJx22KREzE/s1600/MPC%2BBig%2BBore%2BRocker%2BArms.jpg

This is because motoguzzi V engines are the particular design they constantly develop, look at the roller tappets - so nice. Old moto guzzis must share the same problems that the CXes have...

PS. I like motoguzzi, but I don't have money for one...

Re: Schmierölkreislauf

Re: Schmierölkreislauf

Hello in this post again...

I managed to produce a set of shafts for Martin, I think I am ready to make more of them. Some info...

The shaft is surface hardened to 55hrc, the bearings are bimetal type - steel base and bronze on the outside.

The shafts copy the CX650 pattern, so you get oiling points at each of the bearing on two sides. The groove is inside the bearing.

The bearing and the shaft can be fit to your requirements - these are matched to 0.03mm.

They are plugged using stop allen bolts:

PS. open in a new window to get a full-size...

I managed to produce a set of shafts for Martin, I think I am ready to make more of them. Some info...

The shaft is surface hardened to 55hrc, the bearings are bimetal type - steel base and bronze on the outside.

The shafts copy the CX650 pattern, so you get oiling points at each of the bearing on two sides. The groove is inside the bearing.

The bearing and the shaft can be fit to your requirements - these are matched to 0.03mm.

They are plugged using stop allen bolts:

PS. open in a new window to get a full-size...

Zuletzt von bc30se am Sa 11 März 2017 - 17:44 bearbeitet; insgesamt 2-mal bearbeitet

Re: Schmierölkreislauf

Re: Schmierölkreislauf

Great Job, I am very interested

_________________

Ist Spannungsabfall eigentlich Sondermüll?

Digitale CDI-Zündung

Arduino-CDI --> Anschlussplan --> Erprobung/Test

Stammtisch WilderWesten

Re: Schmierölkreislauf

Re: Schmierölkreislauf

Well done, Pavel !!

...What is the price for 1 engine (4 shafts and bearings)?

I have al lot of old old shafts and rocker arms here and I want to rebuild it.

...Sorry I didn´t contact you earlier. I was in hospital and didn´t work a very long time.

...What is the price for 1 engine (4 shafts and bearings)?

I have al lot of old old shafts and rocker arms here and I want to rebuild it.

...Sorry I didn´t contact you earlier. I was in hospital and didn´t work a very long time.

f104wart- Anzahl der Beiträge : 11446

Anmeldedatum : 24.02.13

Alter : 67

Ort : 35315 Homberg Ohm

Re: Schmierölkreislauf

Re: Schmierölkreislauf

Think about the little drill in the rocker arms!

_________________

Ist Spannungsabfall eigentlich Sondermüll?

Digitale CDI-Zündung

Arduino-CDI --> Anschlussplan --> Erprobung/Test

Stammtisch WilderWesten

Re: Schmierölkreislauf

Re: Schmierölkreislauf

Hello again...

It is good that there is some interest....

I haven't made an 'official' advertisement in the sales section yet. I will do it in the future so for now please talk to me on my PM box. Of course you can always send me a combined package and share the shipping costs as we did with gaskets - depending on how many you need.

The price.... I don't think it is cheap, the price I will give you is the minimum price I should ask, I am afraid I cannot get it any lower...

But I will give you information on the PM and you will decide yourself.

the matter is... I know about these holes, I have a set of the 650 holders in my garage now. I can make the holes for you if you wish but.... I have also been thinking about them... and.... I came to a conlusion that.... it is better to stay without them because....

1. I don't know exactly what this hole is for... in all probability it is an end flushing point so there is always fresh oil inside the shaft, or it is there to oil the valve ends.... - very likely honda noticed valve tips pitting

2. This hole means oil may flow out even before it reaches the top bearing - because the arm is filled with oil from the bottom to the top, and it is at an angle in the engine.... you need to fill the whole arm to get oiling in the top bearing....

3. Remember that CX650 has a stronger oil pump that may compensate for this hole...

4. Original CX500 solution - with only 2 holes in the centre of the shaft, is able to serve well above 100.000km.... so why we should bother???

5. I can of course make this hole for you...

The price.... just ask me in the PM now, later on

yours

pawel

It is good that there is some interest....

I haven't made an 'official' advertisement in the sales section yet. I will do it in the future so for now please talk to me on my PM box. Of course you can always send me a combined package and share the shipping costs as we did with gaskets - depending on how many you need.

The price.... I don't think it is cheap, the price I will give you is the minimum price I should ask, I am afraid I cannot get it any lower...

But I will give you information on the PM and you will decide yourself.

Brummbaehr schrieb:Think about the little drill in the rocker arms!

the matter is... I know about these holes, I have a set of the 650 holders in my garage now. I can make the holes for you if you wish but.... I have also been thinking about them... and.... I came to a conlusion that.... it is better to stay without them because....

1. I don't know exactly what this hole is for... in all probability it is an end flushing point so there is always fresh oil inside the shaft, or it is there to oil the valve ends.... - very likely honda noticed valve tips pitting

2. This hole means oil may flow out even before it reaches the top bearing - because the arm is filled with oil from the bottom to the top, and it is at an angle in the engine.... you need to fill the whole arm to get oiling in the top bearing....

3. Remember that CX650 has a stronger oil pump that may compensate for this hole...

4. Original CX500 solution - with only 2 holes in the centre of the shaft, is able to serve well above 100.000km.... so why we should bother???

5. I can of course make this hole for you...

The price.... just ask me in the PM now, later on

yours

pawel

Re: Schmierölkreislauf

Re: Schmierölkreislauf

Guys... I have a small test for you... a primitive test but it shows a lot.

I did it with a sharpened punch. I think I struck my shaft even more forcefully than it was in the case of honda.

Believe it or not, but every money that you spend for a new honda shaft is like throwing money into the bin - and honda asks more than 20eu for a shaft.

Enjoy from poor Poland

https://www.youtube.com/watch?v=_kMIpaDuFjs

If you want me to make more tests - perhaps I did something wrong, tell me what I should do, I will do it and make a video for you but my shaft is much better than the Honda one. I did the test two times. Each time the result was the same... the punch got smashed but the shaft was perfectly ok...

You cannot be wrong with these shafts...

I did it with a sharpened punch. I think I struck my shaft even more forcefully than it was in the case of honda.

Believe it or not, but every money that you spend for a new honda shaft is like throwing money into the bin - and honda asks more than 20eu for a shaft.

Enjoy from poor Poland

https://www.youtube.com/watch?v=_kMIpaDuFjs

If you want me to make more tests - perhaps I did something wrong, tell me what I should do, I will do it and make a video for you but my shaft is much better than the Honda one. I did the test two times. Each time the result was the same... the punch got smashed but the shaft was perfectly ok...

You cannot be wrong with these shafts...

Re: Schmierölkreislauf

Re: Schmierölkreislauf

I think I will be doing the holes in the arms too, so I will improve the setup for Martin too.

Horst wrote to me and gave me his suggestion - I think the most right now:

* - is an oil point/entry

---> - oil distribution

Single point oiling inside - CX500

<<<<- out < ------- <---- * ----> --------- > out ->>>>>

Double oiling point - CX650

<---- * -----> arm exit <------ * ------>

With no exit

<---- * -----> --- || --- <------ * ------>

when the inside of the arm becomes full

<---- * ------------------ | no exit = oil blocked inside - no flow | -------------------- * ------>

the inner side of the bearing will not get proper oil circulation because oil cannot leave properly.....

The hole in the arms, after the design is changed to 2 point oiling system, is rather obligatory....

Horst wrote to me and gave me his suggestion - I think the most right now:

* - is an oil point/entry

---> - oil distribution

Single point oiling inside - CX500

<<<<- out < ------- <---- * ----> --------- > out ->>>>>

Double oiling point - CX650

<---- * -----> arm exit <------ * ------>

With no exit

<---- * -----> --- || --- <------ * ------>

when the inside of the arm becomes full

<---- * ------------------ | no exit = oil blocked inside - no flow | -------------------- * ------>

the inner side of the bearing will not get proper oil circulation because oil cannot leave properly.....

The hole in the arms, after the design is changed to 2 point oiling system, is rather obligatory....

Zuletzt von bc30se am So 12 März 2017 - 14:17 bearbeitet; insgesamt 6-mal bearbeitet

Seite 3 von 4 •  1, 2, 3, 4

1, 2, 3, 4

CX GL500-650 Forum :: Technisches :: Technikecke :: Motor

Seite 3 von 4

Befugnisse in diesem Forum

Sie können in diesem Forum nicht antworten

Startseite

Startseite